SIMA TECHNOLOGY CO., LTD

Established in 1995, SIMA Technology Co., Ltd. (SIMA) is a 100% subsidiary of Muramoto Electron (Thailand) Co., Ltd. (METCO). Based in Thailand, SIMA specializes in precision manufacturing, plastic molding, and medical device assembly, catering to diverse customer needs. With a robust one-stop production system and a commitment to quality, SIMA ensures efficient operations and exceptional reliability across all its services.

■ Business Activities

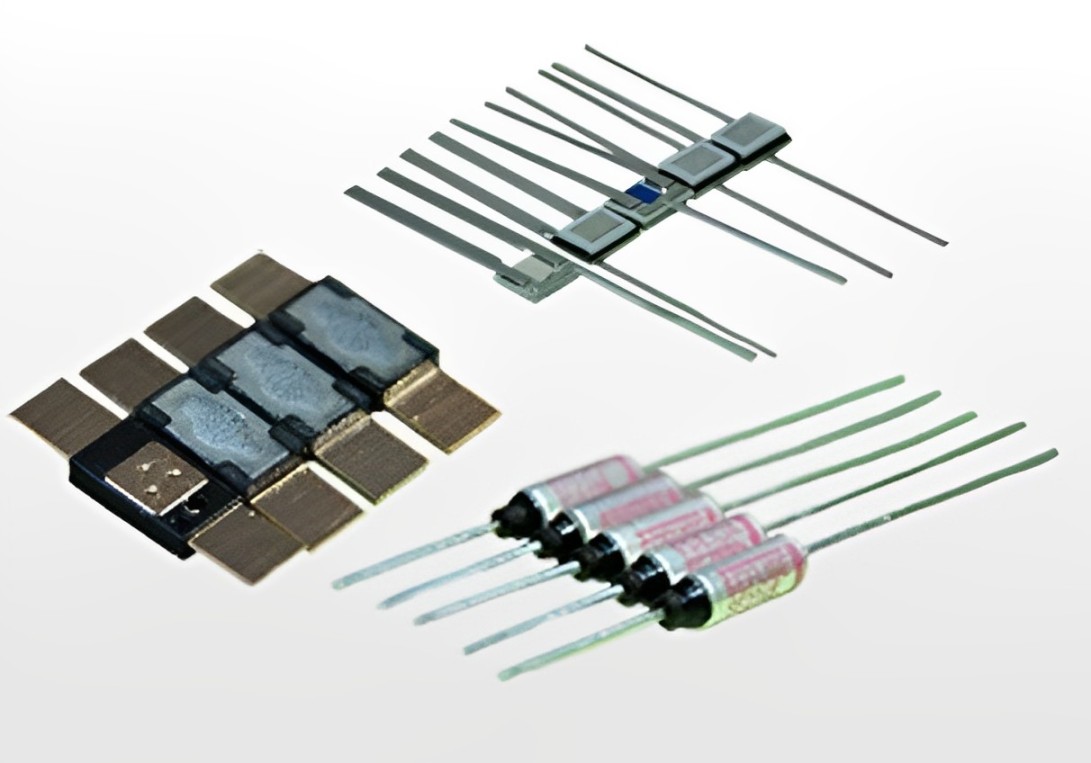

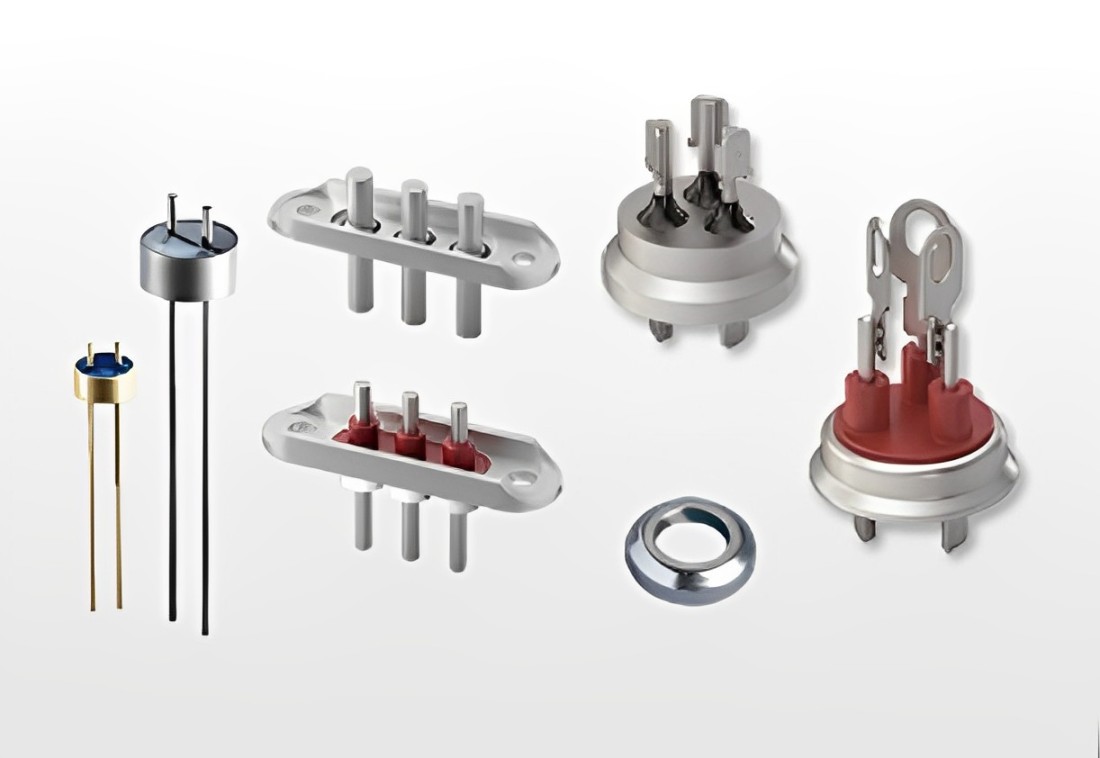

1. Precision Pressing: High-accuracy components for automotive, home appliance, and lens applications

2. Plastic Injection Molding: Production of printer parts and medical-related products

3. Medical Device Assembly: Manufacturing and assembly of medical suction device components

4. Mold Design and Manufacturing: Comprehensive mold design and production for seamless mass manufacturing

5. Custom Jigs and Equipment: Development of tailored industrial equipment

■ Strengths

1. Integrated Production System: In-house management from mold design to product completion

2. High-Precision Manufacturing: Delivering the accuracy required for critical applications in the medical, automotive, and home appliance industries

3. Custom Solutions: Flexibility to adapt production to specific customer requirements

4. Muramoto Group Reliability: Leveraging the expertise and stability of its parent company for consistent quality

SIMA Technology Co., Ltd. is your trusted partner for comprehensive manufacturing solutions. With advanced technologies and a focus on precision, we are committed to meeting diverse industrial needs efficiently.

For more details, please feel free to contact us.

Basic info

Kingdom of Thailand Nakhon Ratchasima A.Pakthongchai 99 Moo.1 T.Thongchainea

044-081-131

1,900,000,000THB

300,000,000THB

1383

https://www.nc-net.or.jp/company/98740/

https://www.muramoto.com/en/locationlist/stc

Web meeting

Japanese / Thai

Metal stamping/Press, Plastic injection, Medical device assembly

Die maker, Packaging, Metal machining

Metal stamping/Press

Plastic injection

Medecal device assembly

Private